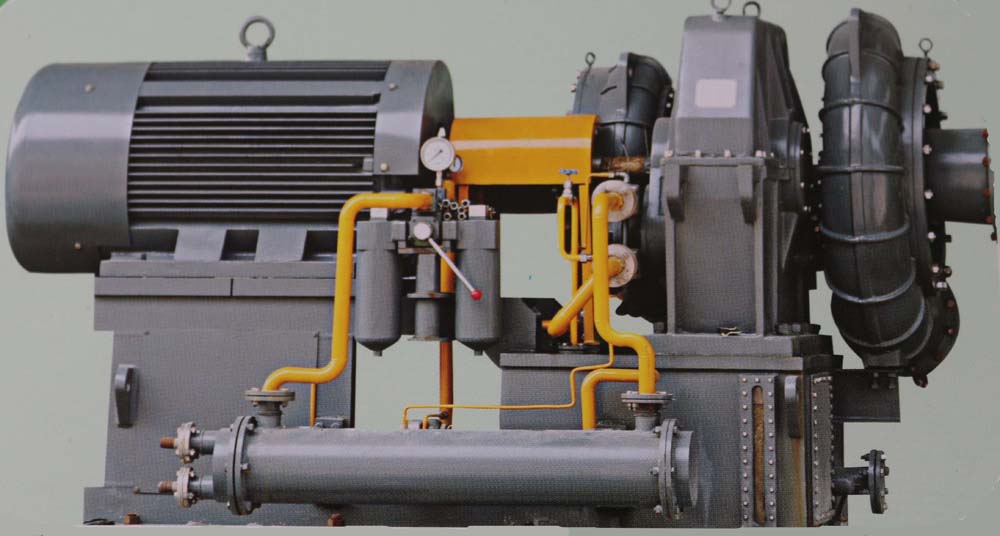

Liquid Ring Vacuum Pump 2BE3

Liquid ring vacuum pump with large pumping speed, energy saving, high efficiency, simple structure, convenient use, etc.The company adopts the German DIN standards, products acquired the CE certificate. Pump body produced by high precision machining centers, CNC machine tools and other advanced equipments. The raw materials have been strictly tested with spectrum analysis, hardness testing, metallographic analysis, performance testing and etc. to ensure that each batch of material conform to the requirements of the order. Each pump has to be inspected with multifunctional test station before shipping. Pumps With cast iron, carbon steel, stainless steel, titanium, and other materials, sealing parts, bearing all adopt international famous brands such as NSK, SKK and so on. The pumps are able to discharge corrosive and flammable gases,such as methane gas and chlorine chemical gases. Liquid ring vacuum pumps are Widely used in papermaking, chemical, pharmaceutical, coal, metallurgy, electronics, chemical fertilizer and other industries.

Introduction:

2BE3 series Liquid ring vacuum pump are the products with high efficiency and energy saving, which are manufactured by our company combining with the advanced technology of the imported products. They are not only can save energy, but also suitable for long-term use and operation.Running in the rough vacuum condition, Liquid ring pump working conditions are often extremely harsh. 2BE3 series products are designed for suction various gases. They can be widely used in coal mine, electric factory, petrifaction and chemical industry, food processing and so on.2BE3 can be used with various actuating devices, such as belt, gear box,synchrony motor, variable speed drives etc. In addition, in order to save space, more than two or at most four sets of the 2BE3 series pumps can be driven by one motor simultaneously. When set a middle wall in the casing, the left and right parts of 2BE3 can run under different vacuum respectively ,if the pressure tolerance between the two sides is lower than 80kP,one pump can completely work like two .This feature further enhances the operational flexibility of 2BE3 vacuum pump

Main features:

1. The gap, corrosion status, fouling situation can be easily observed by the big inspection port on both sides of the pump cover.

2, 2BE3 vacuum pump set the suction and discharge flanges both on the top and sides with the same diameter, so on-site installation is more flexible and convenient.

3. All bearings adopt the imported products in order to ensure precise orientation of impeller and high stability during the running.

4. The material of the impeller is welded with nodular iron or steel to ensure the high stability and increase the lifetime of the pump greatly during any hard conditions.

5. The pulley (when the pump is driven by the belt) adopts standard high precise taper bushing pulley to keep the reliable running and increase its lifetime, also it is easy to dismantle.

6. The pump body is made of steel or stainless steel plates to increase the lifetime of the pump

7. The shaft sleeve as the most easily damaged part, our shaft sleeve is made of stainless steel to increase the lifetime of the pump five times than normal material.

8. Special separator built-on the pump can save the space and reduce the noise efficiently.

9. All the castings by the resin sands with great quality, no puttying. Keep the heat dissipation is the best.

10. The mechanical seals (optional) adopt the imported parts to fully ensure the pump in the long-running process without leakage.